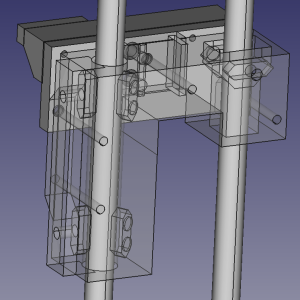

My design for RepRap Lorenz uses printed sliding bearings with PTFE inserts running on stainless steel tubes:

So I thought I’d try printing replacements for rotary journal or needle-roller bearings. Here’s the very first test.

It is pretty rigid, and rotates freely. Obviously there is more friction than a conventional bearing, but even quite a weedy motor would have plenty more torque than is needed to overcome that. The internal structure is just three 10mm x 4mm pieces of PTFE Bowden tube at 120o to each other.

The two things to try next are putting a motor on it and letting it run for a time to see if it wears, and maybe sacrificing some rigidity by adding printed springs under the PTFE to increase compliance to reduce friction further.

EDIT: Update on the 3D printed bearings here.

Connect with us

Keep up to date on the latest RepRap Ltd news:

Pingback:Update on 3D Printed Bearings | RepRap Ltd