Tool definitions

Edit config.g to include the extra tool definitions required for the second extruder.

For multicolour prints it is important the tool numbering starts at tool 0. Historically, tool numbering started at 1. Therefore it is important that you update your SD image to reflect this change. The standard SD images, with the first extruder set to T0, are available here.

An example excerpt is given below, specifying parameters for two extruders:

M563 P127 H1 D0:1:2:3:4 ; Tool 127 allows the web interface to control all drives and heaters

M305 P0 R4700 ; Set the first hot end thermistor series resistor to 4K7

M305 P1 R4700 ; Set the second hot end thermistor series resistor to 4K7

M563 P0 D0 H1 ; Define tool 0

G10 P0 S-273 R-273 ; Set tool 0 operating and standby temperatures

M563 P1 D1 H2 ; Define tool 1

G10 P1 X19 S-273 R-273 ; Set tool 1 temperatures, and X offset from the first nozzle tip

Extrusion

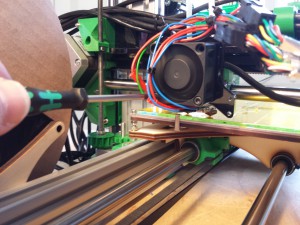

The second extruder can now be commissioned. The same procedure should be followed as for the first extruder:

- Check nozzle heating: Command the nozzle to 200C and verify that heating occurs in a controlled fashion.

- Manual extrusion: Ensure the motors are not energised. Manually rotate the extruder drive gears and verify that material can easily be extruded.

- Extruder drive motion: Command the extruder drive to confirm extrusion occurs as expected.