The other day Richard Horne (a.k.a. RichRap) tweeted “It would be nice if you could chemically soften [3D print material] after printing.” This is a really clever idea – you could make a two-material print with two hard materials that stayed where you put them, then dunk the result in an active bath to soften one but not the other.

If you’ve ever eaten a chocolate with a soft centre (and who hasn’t?) then you’ve experienced something like this. When the chocolate is made the centre is hard sucrose (plus flavourings), so the chocolate retains its shape when the outer chocolate coating is applied. But the enzyme invertase is included in the sucrose centre and causes it to soften gradually to fructose and glucose afterwards.

At the University of Bath colleagues and I once did something that achieved roughly the same effect, but using a different mechanism. We made a dextran gel with concanavalin A bound to the dextran. Dextran is a branched polymer made by repeatedly joining together glucose molecules. It is hydrophilic, so when mixed with water it forms a gel.

The more molecular cross-links there are in a gel polymer, the more stiff, solid, and impermeable the gel becomes, as you would expect. As I said, dextran is already branched. But concanavalin A is a lectin that binds to glucose, so it tended to attach to the glucose bits of other strands of dextran, effectively increasing the amount of cross linking and making the gel stiffer and more impermeable to water (and other things) diffusing through it.

Next is the clever bit (which I can say because it was not my idea, but that of my colleague John Hubble). When you add glucose to the gel, it competes with the dextran in binding to the concanavalin A, effectively detaching some of the cross links reversibly. The result is a gel that becomes softer and easier for materials to diffuse through when you add glucose to it. The material that we wanted to diffuse faster through it was insulin – we were doing preliminary work on an artificial pancreas. The idea was to make a gel barrier material with an insulin store behind it; when blood glucose rose, the insulin would start to diffuse through the gel barrier into the blood.

As I say – this was preliminary in vitro work. For one thing you can’t put an insulin container inside the human body. If it breaks in an accident and releases all its insulin, the person dies very very dead…

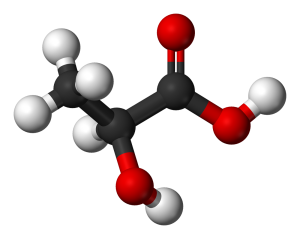

Back to 3D printing. PLA is a polymer with lactic acid (above) as its monomer. Lactic acid is a very sugar-like molecule. Maybe we could add an enzyme to PLA (like the chocolates) that would gradually soften it with time by cutting the long polymer molecules into shorter ones. Or maybe we could bind a lectin or ligand to low-molecular-weight PLA that would bind the small PLA molecules together effectively giving the stiffness of long-molecule PLA. Subsequently putting this material in a bath with the appropriate competitor for the ligand would cause the material to soften. If that competitor stayed in the structure when it was removed from the bath, the softening would be permanent.

This short blog post sounds like a dozen research projects in the making to me…

Adrian

Connect with us

Keep up to date on the latest RepRap Ltd news:

I have been thinking alomng the same lines Adrian. PLA is such a versatile, and acceptable polymer that it does need more research activity. I have been trying to find the Universities and more importantly thye professors who would be interested in pursuing more investigations – already have the manufacturers lined up for when the applications are oidentified, but the research side needs coordinating. If you know of any individuals to contact I would appreciate their contact details,

Iain Duncan

Mousetrap innovation Ltd

Hi Iain –

I can give you a few names, yes. I’ll e-mail you with details.

Best wishes

Adrian