If you just use water in a lasercutter’s cooling system, eventually bugs will grow in it and it will go green and clog the valves, pump, and – worst – the laser tube. Manufacturers recommend changing the water regularly, but that is a pain and you want to minimise downtime. So some people add a biocide like Milton fluid. This certainly keeps the bugs at bay.

But some of the components of the coolant circuit will be made of stainless steel. We noticed in our lasercutter that these were beginning to corrode, so we drained it and did an experiment.

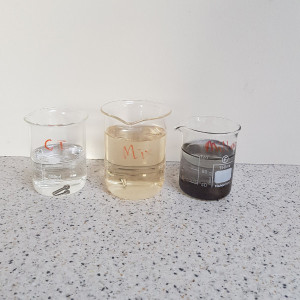

Here are three beakers. Each has a candidate solution in, plus a stainless-steel screw. On the right just Milton fluid has been added, and on the left just central-heating corrosion inhibitor. In the middle is a mixture of the two.

At the start of the experiment about two weeks ago the two single-solution beakers were clear. Mixing the two fluids immediately produced a pale brown solution (middle beaker) even before the screw was dropped in.

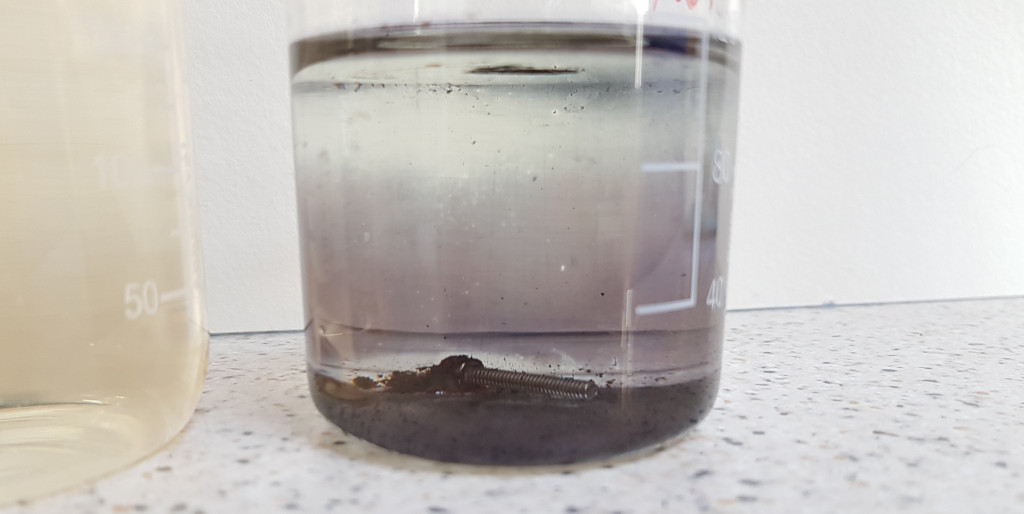

The two on the left have not changed over the course of the experiment, but the Milton fluid beaker on the right has corroded its screw badly. (Chlorine is known to corrode stainless steel.) None of the beakers has gone green with invading microbes.

The conclusion is clear (or rather cloudy grey): Milton fluid corrodes stainless steel.

We shall be using central heating corrosion inhibitor in our laser cutter from now on. We will keep an eye on one possible problem: the inhibitor is designed so that it will also seal small leaks in a central heating system by forming a solid plug when the water is driven off by the heat; this might conceivably cause blockages if water evaporates, but keeping the water topped up should ensure that that does not happen.

Connect with us

Keep up to date on the latest RepRap Ltd news: