Most recycling streams are not set up to process PLA, despite the fact that PLA is probably the most widely-used 3D printed material and is easy to recycle in a number of ways. This needs to change, and the 3D printing industry should lobby for such a change.

In the UK our kerbside recycling collectors don’t take compostable materials manufactured for industrial composting (This includes food packaging made from PLA). The problem with PLA recycling is not that it is difficult; it is, perhaps, the easiest plastic to recycle from a technical point of view because it can both be commercially composted or reground. The problem is that – because it does not have a unique identifier like, say PETE:

it cannot be separated in the processing stream. If it is accidentally mixed with other plastics (like PETE) it contaminates them. The solution to this is obviously to give it its own identifier and separate it in the same way that the other plastics are separated, whereupon the contamination problem would go away. PLA could then be sent to an industrial composting facility, or sent for regrinding and re-use.

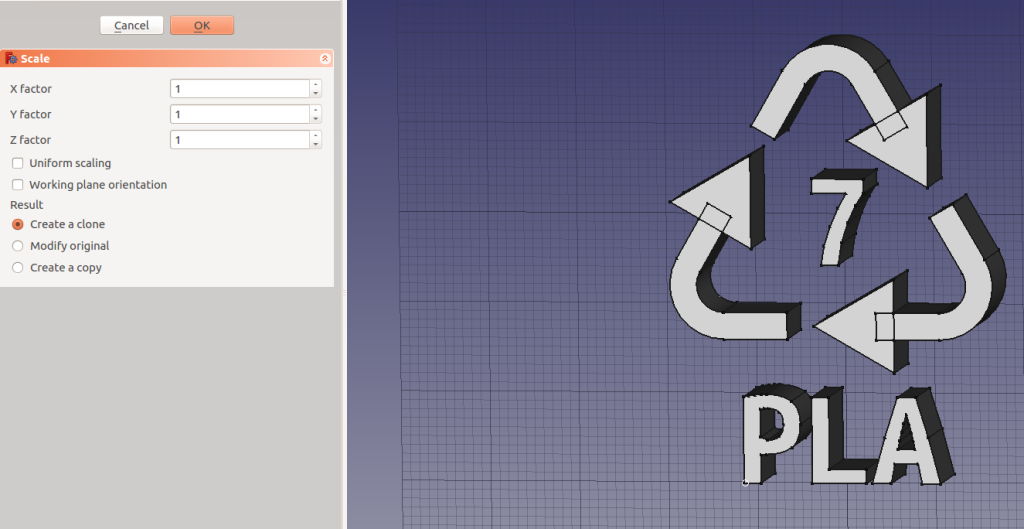

The resin recycling code for materials like PLA that are not currently widely recycled is 7 with the word “OTHER” under the recycling triangle symbol.

We have designed and uploaded 3D design files to our GitHub for such a symbol with “PLA” under the triangle. They are intended to be included in 3D printed designs (all of them…) that are to be printed using PLA.

A quick test print using a design we are currently working on for another project

Scale the shape appropriately, then position it so that it cuts one or two millimetres into a surface of the printed object in a face where such an indentation won’t matter. If you put it in the base of an object most RepRap and other 3D printers will print the indentation well without support.

The master file in our Github repository is a FreeCAD design for the shape: PLA-recycling-symbol.fcstd

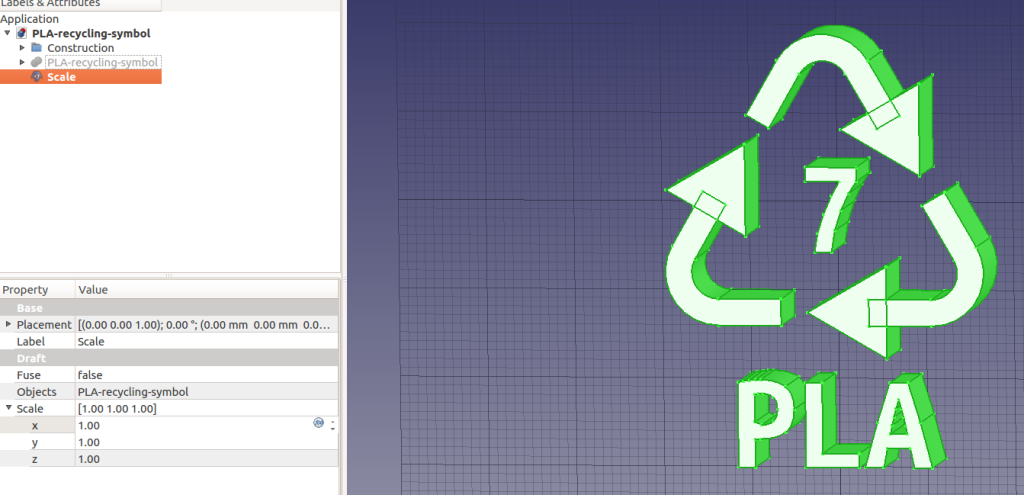

To scale a shape in FreeCAD select the Draft Workbench, select the shape, and from the Draft tools select Scale. Select a point on the shape and then select create a clone and hit OK.

This then gives an extra X, Y, and Z scaling parameter for the result which will allow you to make it any size you like.

The design is also available on Github as a STEP file for other CAD systems, and as an STL file.

Here are some links on PLA recycling:

Recycling Failed and Waste 3D Prints into Filament: Challenges Ravi Toor, Filamentive, 25 February 2019.

Is recycling PLA really better than composting? Jan Willem Slijkoord, 3D Printing Industry, 28 May 2015.

Plastic recycling: just because it’s plant-based (PLA plastic), is it better? Blake Lindley, Edge News, April 20, 2017.

So what do you do with your PLA? Comment below.

Connect with us

Keep up to date on the latest RepRap Ltd news:

This is a great idea

To increase the uptake on using this functionality would it be possible to implement a standard that could be added to the slicing software ?

The appropriate logo could be manually placed and scaled and based on the material profile, the correct identifier could be applied.

I think the main challenge would be to get all the slicing vendors to implement

Yes – that would be technically possible. But I can see a problem with it: the slicer would have to put it on a flat surface (which would be easy to find), but it would have no way of knowing if the designer wanted that surface actually to be really flat for some engineering reason. If it’s included in the design the designer has full control. Admittedly that does imply knowing which plastic an object is to be printed in at the design stage, which may not always be available information (especially for designs that are downloaded from repositories). Perhaps your system, but with the user able to click on a face in the slicer to select where the symbol will appear?