Our Fisher kits have had a revamp and are now shipped with a MasterSpool and MasterSpool refill of PLA. We have modified the Fisher spool-holder spigot design and the side-panel DXF files to hold Masterspools. We have rearranged some of the packing, but the main difference is that we are now supplying 850g reels of PLA to get you started – that’s enough to print you another four sets of Fisher Printed Parts!

MasterSpool was an idea that came from Richard Horne (RichRap) and is designed so that the MasterSpool can be reused again and again, saving on single-use plastic spools, shipping costs from suppliers and – if you did want to reuse your spools in the past – winding filament onto a spool by hand.

We have been using MasterSpools in-house now for over a year and all new filament we order to include in our kits, for production and also for customer print requests, is all MasterSpool refills.

So how do I print a MasterSpool on my Fisher?

Our Fisher Full Kits come with a MasterSpool printed in one of our big production 3D printers. MasterSpools are normally printed on a 200 x 200 mm2 bed and so are too big to fit on Fisher’s build plate. Therefore we have had a bit of a chop about with Rich’s V4 design and created a MasterSpool that can be printed in sections. If you want to print our MasterSpool the design is in our Github repository here.

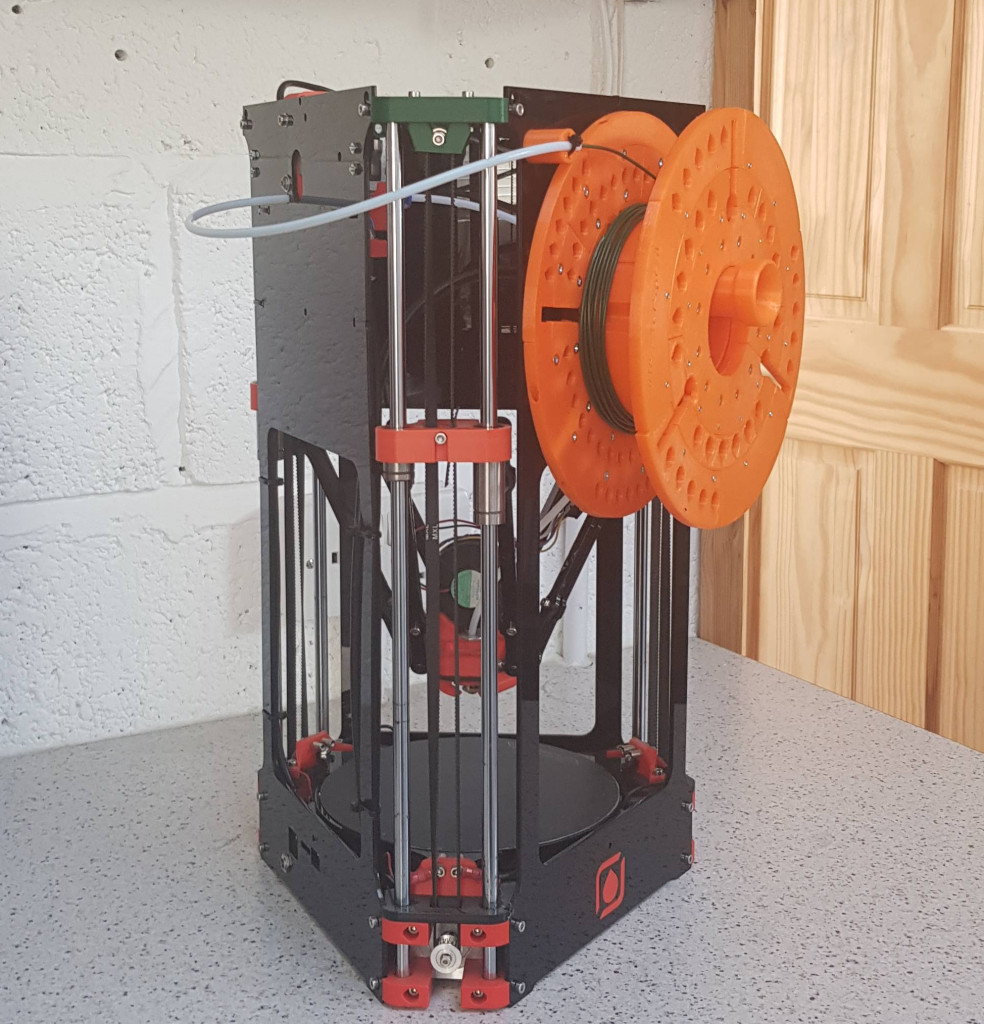

This picture shows the new Masterspool design holding 2.85 mm filament. It will hold the 1.75 mm filament which we supply for Fisher as well, of course.

You may have also noticed we have increased the cost of our Fisher kits a bit. This is because volumes of components we are ordering has decreased, therefore we aren’t able to take advantage of the larger volume price breaks offered by our suppliers, and because of the greater amount of filament we are supplying with every kit, and the printed Masterspool that we are including in Full Kits.

At RepRap Ltd we want to ensure that our business has minimal environmental impact. We have 4KW of solar panels on our roof, and any extra electricity we use also comes from renewable sources. We print almost exclusively in PLA, which can be recycled (though we need to keep up the pressure for PLA recycling streams to be increased), and also can be commercially composted. And now we no longer supply disposable 3D printer filament reels made from oil-based plastics with our kits, but only re-usable PLA Masterspool reels that are made by our RepRaps themselves. We also reuse or recycle any packaging we can that our suppliers send to us. For sending out Kit and other orders we use Jiffy Green padded bags or recyclable boxes. If anyone has a green alternative to grip-seal bags that don’t cost 1000% more than regular ones – let us know!

Connect with us

Keep up to date on the latest RepRap Ltd news: