RepRap (and other) FFF 3D printers have had heated beds to ensure prints don’t peel off for a long time. I think they were invented by Chris Palmer (Nophead) in 2010. They have also had magnetic beds to hold a thin steel sheet on which to print, so that the sheet can be removed and flexed to separate the print easily. I think Josef Průša invented this idea.

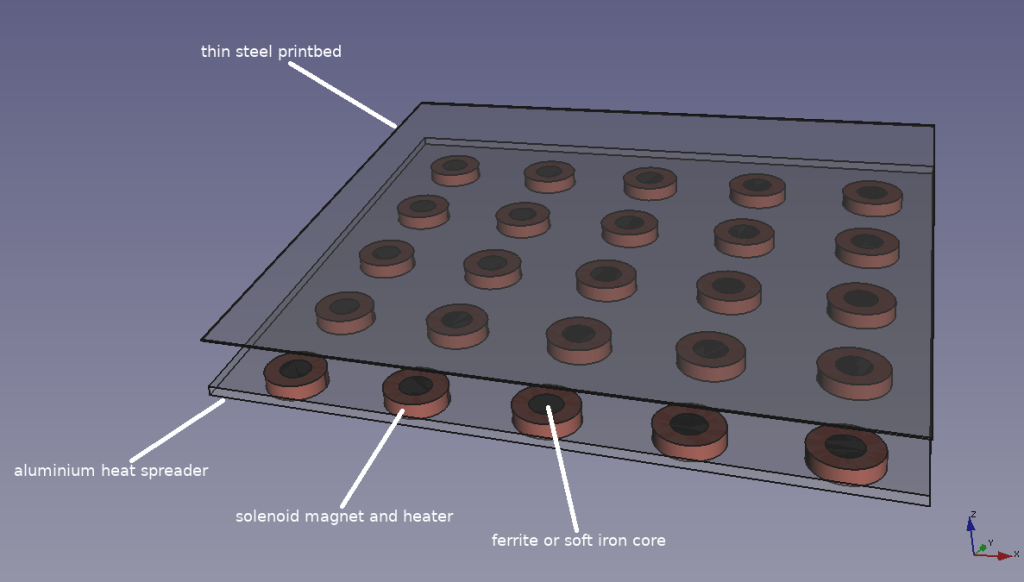

So I thought, “Why not combine these?” The picture above shows what I mean. This would give an electromagnetic attachment between the thin sheet and the printer. The printer’s controller turning the bed heater on or off would also turn the magnet on or off.

Then, when the print was finished, the magnets could be automatically turned off, and a simple movement of the hot end could then push the thin sheet with its print on it from the machine. A similar mechanism could be used to load a blank sheet, and the next print could be started. In other words, this would allow continuous unattended printing of as many parts as you liked, with the RepRap 3D printer as a manufacturing component of a production line. This has long been a goal of ideas like printing on a continuous belt.

To get a controlled temperature, the solenoids under the bed would have to be driven by pulse-width modulated power smoothed through a low-pass filter (that is, a capacitor), so the magnets were always on (and the sheet was not vibrating…) when heat was needed and the print was being printed. It should be a fairly simple electrical calculation to get the right number of solenoid coils and average current to generate both the heat and the magnetic field needed, especially as the PWM values required for a given bed temperature in a RepRap can be logged. The flexible sheets might need to be made from a ferromagnetic material that couldn’t be permanently magnetised (just like the solenoid cores) to prevent them sticking after the field was turned off. Again, this should not be difficult to achieve.

This blog post is to get the idea out to prevent it from being patented. As soon as I had it I thought it was so obvious that someone must have thought of it before. But I did an online search, and could find nothing – so maybe I am the first. But if I’m not please e-mail with a link to its first appearance and I’ll put an acknowledgement at the head of this blog post.

Adrian Bowyer

Connect with us

Keep up to date on the latest RepRap Ltd news:

Fascinating. Could a pattern of rapidly flipped polarity of the solenoids be used to cause the bed to move in a direction (IE off, pulling another behind it)?

Maybe. What you’re describing is a linear induction motor. Normally the moving part of those is not ferromagnetic (it’s usually aluminium). But it might be possible to make a linear version of a stepper motor, which would work as you describe.

Like a magnetically levitated train ?

https://youtu.be/T1WXYF9OW8I?t=494

Yes – they work with non ferromagnetic conductors (usually aluminium). But we need something that can be made to stick down fast with the DC component of the field when the actual print is being printed, which that wouldn’t do. Perhaps a combination of materials? But it’s starting to get complicated. I think it’s important to make the system as simple as possible. And you always have the movement of the RepRap itself that can be used to shift things about as long as there is little friction.

We were actually discussing this at our meetup about 4 months ago.

What you actually need is an electromagnet with a magnetized core. That is, without any power applied, the magnets hold the steel plate on the bed. When the print is finished, you apply power which COUNTERS the permanent magnet’s attraction, making it easy to remove the plate.

You also need mechanisms to push the plate off the bed and slide a new one on. Could be crudely done with solenoids. Push the loaded plate onto a trolley of some sort, roll a new plate into place, maybe from the rear.

I disagree. With my proposal you get both heating and magnetism from a single system – much simpler. And removing the plate can be done by the RepRap itself – it just needs to push sideways on a printed part that it has made. You could then have a plate chain, with a blank being pulled into place and magnetically clamped down.

Are you aware of any electromagnetically heated hotends ?

I’ve considered using a Metcal soldering system. The desoldering tips are especially appropriate as they plug into a standard power supply and have a tube from the rear to a choice of front holes, just like a common reprap nozzle. Metcal tips are heated by magnetic induction at 13.56 MHz and temperature stabilised by the Curie effect and skin effect. This is less appropriate for FDM printers as a choice of temperatures seems to be necessary and in the Metcal system this would require a selection of nozzles.

I propose an electromagnetically heated tip tube and nozzle, isolated thermally and electrically from the extruder with a borosilicate tube. The nozzle then has low thermal mass and can be more precisely controlled with a faster response. Temperature of the nozzle could be measured with a non-contact radiant thermometer similar to MLX90632 or possibly a thermocouple and the glass tube would give good isolation from the extruder gears.

Yes – I do know about Curie effect heat stabilisation. But – as you say – a 3D printer needs to work at a range of temperatures. I see the advantage of what you propose over a simple resistive heater with temperature feedback to the control system in speed response, though.

Why not just using coils to hold the build plate in place? Keeping the rest as is. Easier to build.

I think that’s what I proposed… The coils also do the heating.

Suggest a hybrid approach which could be made to work quickly without designing and building coils.

A) use 3 or 4 small and simple electromagnets around the edges to hold the steel sheet down or in place.

B) rather than design or build coils and drivers use induction hob components – coil and inverter drive operating at 20 kHz. These are cheap, about the right size and readily available plus work from mains ac.

The sheet needs to be held down all over, otherwise it tends to bow. You could use induction heating, but – given you have to have the coils – you may as well heat with them too.

It’s amazing how people think about the same things but hold off publishing the ideas before they are fleshed out. There’s even an old saying that cautions against making too much noise before you actually lay the egg.

I was looking at incorpotating electromagnets to a mains powered heatbed a few months ago but never got to building it. I think it’s better to keep PWM modulated heating element separate from magnets. Makes electronics simpler and cheaper as it avoids the need to smooth the output and will work better with AC powered beds too.

But smoothing the PWM should only need one capacitor. Then you need zero changes to the firmware – the heat bed G and M codes automatically also then control the magnets.

My earliest recollection of magnetic spring steel beds for pop off prints were from experiments that Nophead did back in the day – I see there is also a post on the blog about that initial prototype (in Jan 2010!) : http://hydraraptor.blogspot.com/2010/01/quick-release-bed.html

Did Prusa also do some early research into that? It looks like his very neat PCB heated bed arrived on the reprap wiki in Aug 2010, but I don’t remember anything about a magnetic bed.

I had forgotten that one! Thanks for reminding me. It may well be that my subconscious remembered and that led to my idea of combining the magnets with the heater to allow them to be turned on and off.

Hi, i am trying to figure out, how you want to convert the electricity to heat? When reading coils, i think of inductive heating elements. However those won’t work with a filtered pwm signal. Are you still trying to heat the coils by raw current running through (joule heater like pretty much all beds are)? Being a hobbyist myself (no extensive education in engineering, physics or anything like that) i want to apply heat via inductance, not at least because of efficiency. I guess your idea might be a great inspiration to such an approach. What about placing permanent magnets beneath a huge inductor coil. I don’t really expect vibration issues with switching rates well above 30khz. As soon the printer is finished and you want to remove the sheet, you push a button which feeds the coil with DC, opposite to the permanent magnets? This way the plate would come loose. However i don’t know how I could reliably read temperatures from this sheet. I would expect huge currents generates in the leads of an ntc thermistor or thermocouple. What are your ideas about that?

I wasn’t proposing to use induction for two reasons: the high power and frequency might interfere with the other electronics, and it would be no more efficient than simple ohmic heating. Induction does give more rapid response to load changes, but that’s not needed for a heated bed, which needs to stay at a constant temperature.

And I thought I had an original idea! 😉

You don’t need to smooth the solenoid power with a capacitor, the inductance can do that for you. Just add a Schottky fly-back diode so that when the PWM is off the current circulates through the inductor and falls slowly. Provided your frequency is high enough, relative to the inductance of the coil, the current will be almost constant, just a shallow saw tooth, rather than a square wave.

Hi Chris! Good to hear from you, and good idea.

I’m looking at creating a large 3d printer from the guts of a FarmBot Genesis, I’ve considered a couple different ways to heat the bed but not once did I thing about electromagnetic inductance.

having a removable magnetic bed would be be a huge deal for me because I would like to print on a mirror, and only heat/ print sections of the bed that are needed. So if I layered it mirror, aluminum, magnets, do you think I could efficiently heat my bed sections

Yes, I think that would work, except for heating regions if you have an aluminium plate. Aluminium is such a good conductor that I think the heat would spread anyway. Plus, if you are going to heat only regions of the bed, each region will need its own temperature sensor to feedback to the controller.