Investment casting, or the lost-wax process, is one of humanity’s oldest technologies. A wax master model is made, and repeatedly dunked in liquid clay slip then dried. Each dunk adds a few millimetres of clay until the wax master is

Fire and Fury

Investment casting, or the lost-wax process, is one of humanity’s oldest technologies. A wax master model is made, and repeatedly dunked in liquid clay slip then dried. Each dunk adds a few millimetres of clay until the wax master is

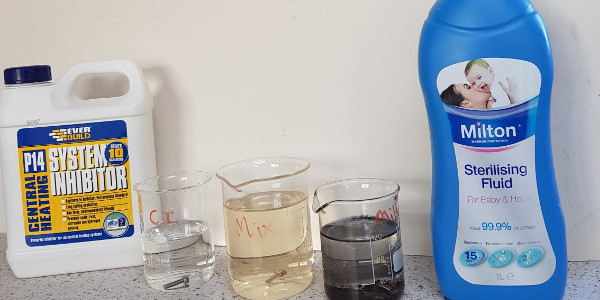

If you just use water in a lasercutter’s cooling system, eventually bugs will grow in it and it will go green and clog the valves, pump, and – worst – the laser tube. Manufacturers recommend changing the water regularly,

This is a brief blog post to get an idea into the public domain to prevent its being patented. I’ll probably work up more detail later. Plastic extrusions are widespread: guttering, pipes, curtain rails and so on are all examples.

Sadly the printed bearings in the previous post do not work as well as one might like… I put it in a lathe at 200 rpm for 10 minutes and the PTFE bearing surfaces wore terribly badly. Sigh… However, we

My design for RepRap Lorenz uses printed sliding bearings with PTFE inserts running on stainless steel tubes: So I thought I’d try printing replacements for rotary journal or needle-roller bearings. Here’s the very first test. It is pretty rigid, and rotates freely. Obviously

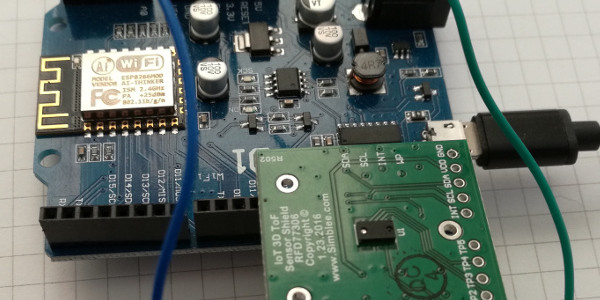

The Simblee RFD77402 distance sensor (thanks to Victoria Stamps on Twitter for bringing it to my attention) is not very big and not very expensive (about $6). It is the little black chip on the green carrier: It is an

On Wednesday I was invited to a rather nice dinner at Birmingham Town Hall organised by TCT to attend their awards ceremony, which was in association with their 3D Printing Exhibition at the National Exhibition Centre. On the left is Kryten from Red Dwarf (or rather,

As followers of this blog will know I have been working on a new RepRap delta design – Lorenz. It has a number of novel features and it also contains a very high proportion of self-printed parts. I haven’t finished it yet,

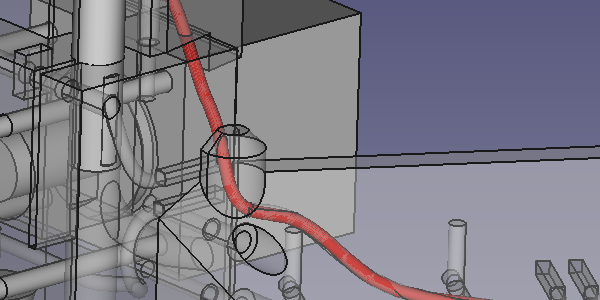

A characteristic that a lot of 3D printers share is having wires running all over them. These are often neatened in places with cable ties, but they still look scruffy and often get in the way of the machine moving,

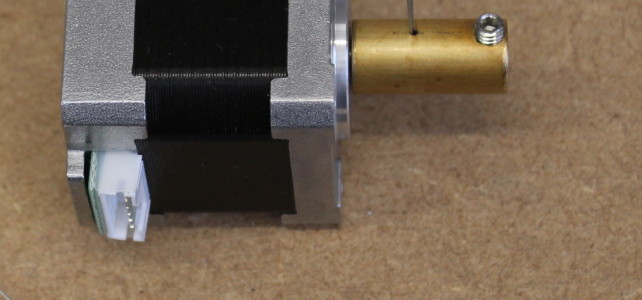

Bye Bye Belts! RepRap Lorenz does not use timing belts. Instead it is driven by wire wound helically on a pulley on each stepper motor. The error caused by the change in wire angle as the helix winds 300mm of wire is about