In 2018 we posted about our aluminium foundry and how we would like to use it to cast aluminium.

We were working on a number of projects so it is not until now that we have now printed a model and dipped it in clay slip and fired it in our kiln.

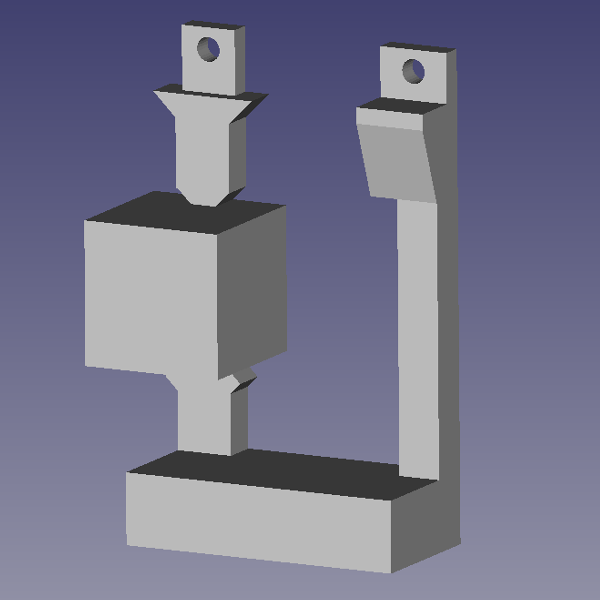

The model (shown below) was printed in Das Filament Natural PLA to ensure there would be minimal residue when it was burnt.

We need to work on our clay slip mix, but other than that the results were pleasing.

The clay was damaged as the wire holding it up deformed in the heat and the clay part dropped and snapped in two in the kiln. But we still have a workable fired mould to fill with aluminium. The inside surface looks smooth.

The experiments continue…!

Adrian, fire up the furnace!

Connect with us

Keep up to date on the latest RepRap Ltd news: