This assembly robot was made by Benjamin Jenett and Neil Gershenfeld at MIT. As you can see, it crawls over the structure it is building placing identical standard cubic blocks wherever it wishes. It is capable of building large-scale structures; structures much bigger than itself.

It occurred to us that there are some possible extensions to this work:

- Have electric power and signals running through the blocks and connecting at each face. The robot could then pick up power and instructions from these and not need to be self powered.

- Have two attachment mechanisms: magnets, to allow blocks to be attached and later removed to be placed elsewhere; and glue to produce a hard permanent high-strength join between the blocks. The glue could be applied by the building robot when a block was in its final destination position.

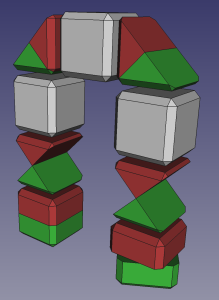

- Have the robot made out of blocks that are geometrically congruent to the blocks that it is building with. These robot blocks would be active. There would be two kinds of active block: the first would be able to rotate about one mid-plane of the block and the second would be able to rotate about one axis through the middle of a pair of opposite faces. The first sketch of the proposed robot is this:

The blocks have small gaps between them for clarity in this exploded picture. The grey ones are just passive, like the building blocks. The red and green ones would be able to rotate about the axes illustrated. As you can see, in its simplest orientation it would just be a straight row of nine blocks, which should be easy to assemble.

This robot would obviously be able to build a copy of itself and to glue that together.

The parts for the built structure and for the robot would be printed in a RepRap 3D printer (which is also able to print its own parts, of course). And one block-framework that the robot could build might be the frame for another RepRap. So we’d have a self-replicating and self-assembling complete system (though, just like RepRap, it would need some parts from outside such as motors and electronics). The RepRap would make the parts of the assembly robot and the passive blocks, and the assembly robot would then assemble both copies of itself and the frames for more RepRaps.

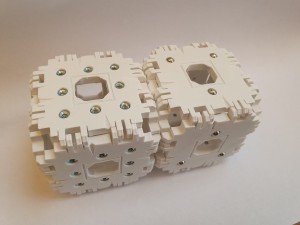

So far we have designed the passive blocks, which are 60x60x60 mm3.

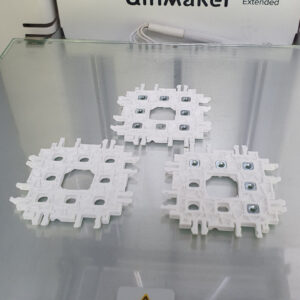

They have two types of faces: three each with three embedded spheres, which are 5mm diameter magnets; and three with eight embedded nuts; these are for the magnets to attach to in any of the four possible orientations. The faces are printed flat and then clipped together along their edges. You can also see the wedge shaped indentations on each edge down which a small quantity of cyanoacrylate glue can be dribbled to give a much stronger bond than the magnets.

When just the magnets are holding the structure together it is editable by the robot. The glue the robot applies will then fix it permanently.

This picture shows the printing of the faces with the embedded nuts paused for those nuts (square M3) to be inserted. The print is then resumed, entombing the nuts. The nuts are also accessible from inside the cube to allow structures and components (such as PCBs) to be attached to the inner walls with M3 screws. This doesn’t interfere with the operation of the magnets. The magnetic spheres just push and clip-fit into their cavities in the other sort of face.

The octagonal holes in the centre of each face are for holding a 15 mm2 PCB with four spring contacts to connect the cubes together. Two of these will be for power (either 12, 5 or 3.3 volts; we haven’t decided yet) and two will be for I2C data transfer around the structure both as it is being assembled and after it is finished. The square gutter round each hole is to prevent the glue dribbling over the PCB.

The next stages are to make more cubes plus the electrical connecting PCBs for each. And then we’ll design and build the construction robot.

All of this work is open source under the GPL and is here on Github.

Connect with us

Keep up to date on the latest RepRap Ltd news: