DRAFT – these instructions are not final, and are likely to change.

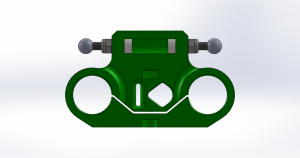

Connecting rod joints

You will need the following parts:

|

|

Linear bearings

You will need the following parts:

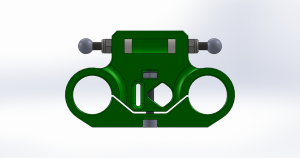

| Push the nut into the centre recess, then fit the cap head screw, leaving it loose. |  |

| Slide each linear bearing into the printed carriage. The Long series bearing must be fitted on the same side as the narrow slot (near the centre of the printed carriage). |  |

| Lock the linear bearings in place by tightening the cap head screw. The bearings should protrude above the carriage such that the slot is just showing. |  |

Repeat

| Repeat the above steps until you have three assemblies. |  |