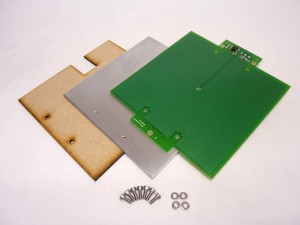

| Peel the protective film from the aluminium heat spreader. |

|

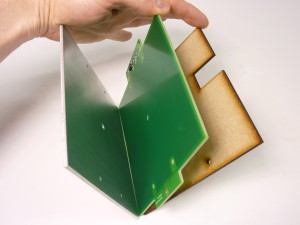

Note that the aluminium heat spreader has a recess in the centre on one side. This is the side the faces the heated bed PCB. IMPORTANT: make sure that there is nothing that can scratch the PCB. The aluminium should be clean, and clear of any burrs, scratches, or sharp metal edges. You can polish it with wire wool or fine sandpaper. Just make sure it is clean afterwards.

|

|

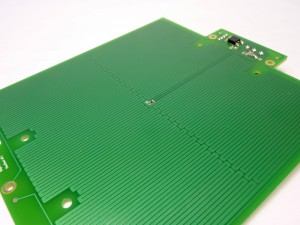

The central hole in the aluminium heat spreader accommodates the tiny surface mount thermistor in the middle of the PCB. Take care when sandwiching the parts together that the edge of the recess does not hit the thermistor – you don’t want to knock it off… NOTE : The thermistor should be electrically insulated from the Aluminium heat spreader. You can add a small piece of Kapton tape over the thermistor, if it is somehow touching the aluminium plate.

|

|

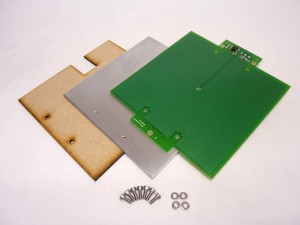

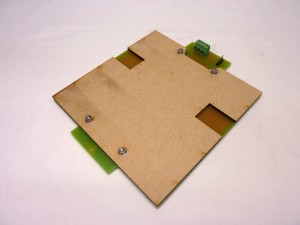

Assemble the heatbed components. From the left to right in the picture they go: Aluminium heat spreader (central hole towards the PCB), heated bed PCB (circuit side towards aluminium heat spreader), MDF insulator. The notch in the MDF aligns with the Y axis motor mount, so that the bed can be as low as possible, but can still move the full distance in Y.

|

|

Put washers under the heads of the four M3x8mm screws and screw them through the stack to hold it together. The ends of the screws should end up below the top of the aluminium heat spreader. Don’t overtighten them; they thread in to aluminium, so you may strip the thread.

|

|

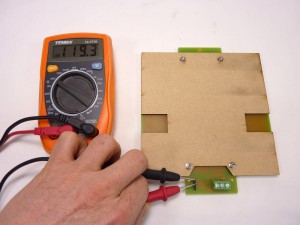

Test the thermistor. Set your multimeter to measure in the 100k ohm range, and measure the resistance on the two pins furthest from the edge of the bed, on the block of four pins. The resistance should be around 100k ohms, with an ambient temperature of 25C. It will be higher if it is colder, and lower if hotter. Also test from one of these two pins to the aluminium plate – this checks for any short circuit between the thermistor and the aluminium. It should have infinite resistance, ie no connection.

|

|

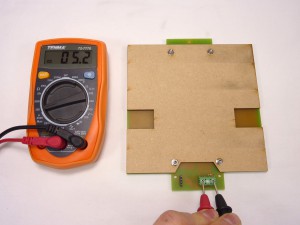

Test the heated bed resistance. Set your multimeter to measure in the 10 ohm range, and measure the resistance on the two outer terminals of the screw terminal block. The resistance should be around 5 ohms. Often this can take a few moments to settle. Also, make sure your multimeter has a good battery in it, or you may get an inaccurate reading. Finally, test for any connection between the aluminium heat spreader and the screw terminals; if there is, the aluminium is making contact with the bed circuit, and the PCB may be damaged. Disassemble and check.

|

|