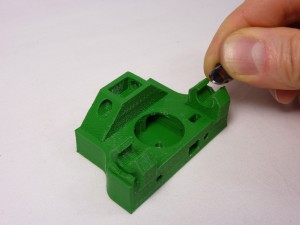

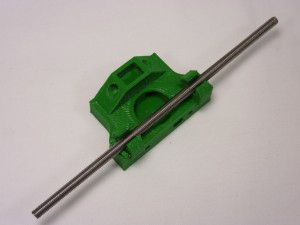

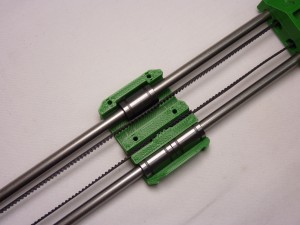

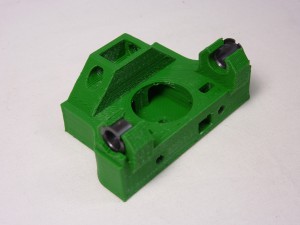

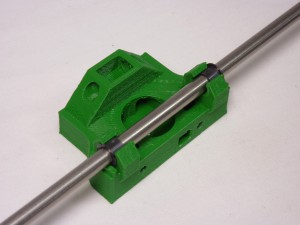

| Start by fitting the Igus bushings into the x ends. These bushings need to allow the Z smooth rods to slide easily bt without much slack. In order to achieve this, you will need to fit an Igus bushing into position and slide a smooth rod through it. |

|

| The bushings can be curled up slightly to fit in downwards. The rims are retained by slots in the 3D-printed parts. Do not attempt to put the bushing in with the smooth rod running through them – this will break the printed part. Put the bushing in on their own, then run the rod through afterwards to check them when they are in place. |

|

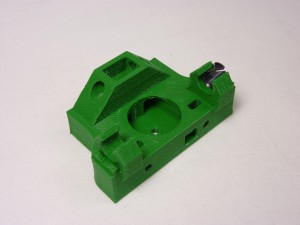

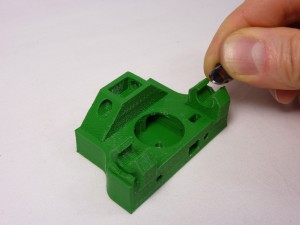

| If the fit is too tight, remove the igus bushing, then remove a small amount of material from the X end. Either use the half-round file to remove material, or clamp a 7mm drill in a vice and run the X end up and down it by hand. Take care – it’s better to remove too little and to have to repeat the procedure, than to remove too much irrecoverably. |

|

| Try the smooth rod through the bushing again. Repeat this procedure for all four bushing positions. |

|

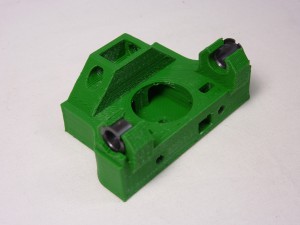

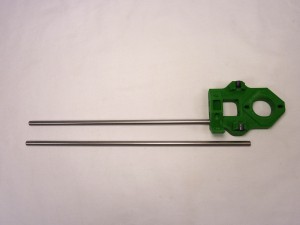

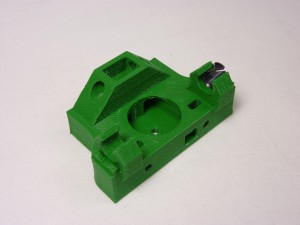

| The holes in the two ends of the X axis where the smooth rods will be fitted are very deep and tend to be very tight fitting; you should ream these out before assembly. Clamp a 6mm drill in a vice and run the holes up and down over it by hand. Again take care not to remove too much – you want a snug fit. |

|

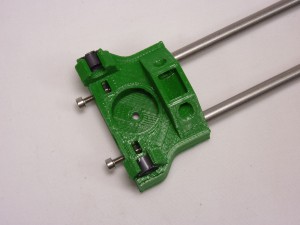

| Run a 5.5 mm drill through both Z-axis threaded rod holes (top right in the picture above); these holes must allow the threaded rod to pass through with clearance. |

|

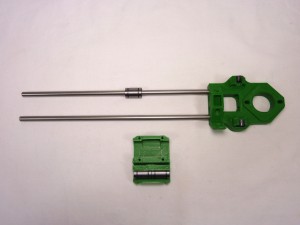

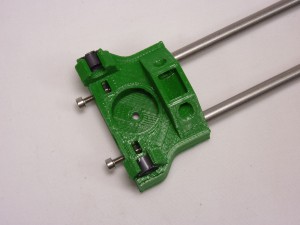

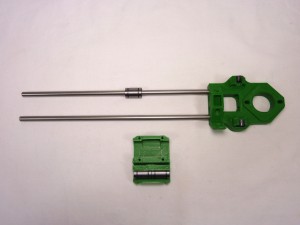

| Slide two linear bearings into the bottom of the X carriage from the side, rather than downwards, otherwise you will break the clip. |

|

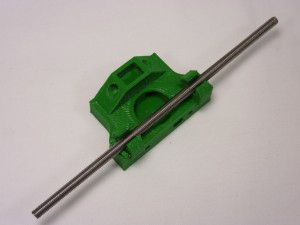

| You can now insert the smooth rods into the X motor end, and slide the other linear bearing onto the top rod (you may need to de-burr the end of the rods with a file to get the bearings on). The smooth rods go a LONG way into the motor mount; make sure they are both fully inserted before you go further. |

|

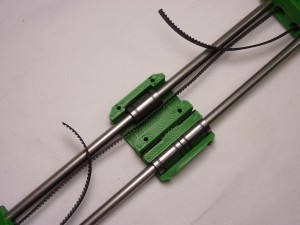

| As with the Y axis smooth rods, if the linear bearings are a little tight, place the smooth rod into an electric drill, then spin the rod whilst rubbing it with a scouring pad. The linear bearing should slide freely along the rod, but without too much play. |

|

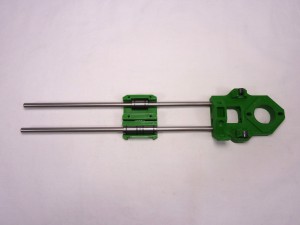

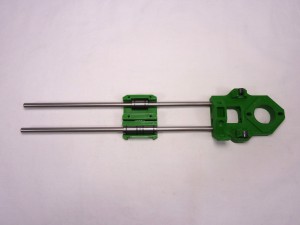

| Put the X carriage onto the rods. |

|

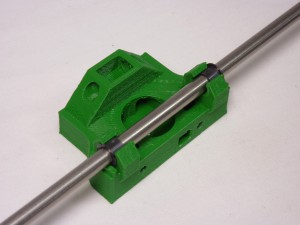

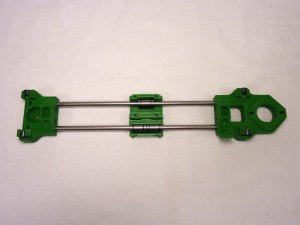

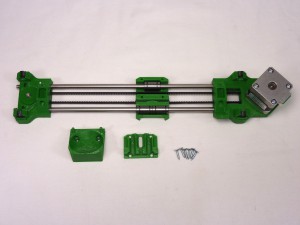

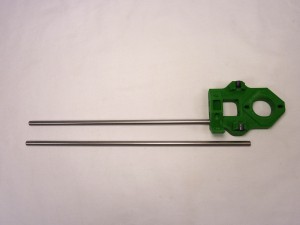

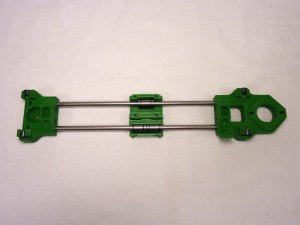

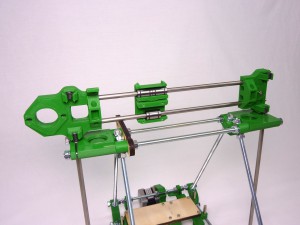

| Add the X idler end, at which point your X axis assembly will look like this: |

|

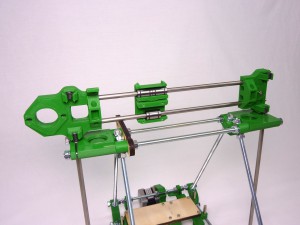

| Drop two nuts into the slots in the idler, and put two screws into them. Leave them loose. These are used to adjust the gap between the Igus bearings at each end, to match the gap between the Z axis smooth rods, by pushing on the ends of the X axis smooth rods. |

|

| Set the distance between the clip bearings to be close to the distance between the Z axis smooth rods. A simple way to do this is to place the X axis assembly above the frame, and looking down through the clip bearings, check that they line up with the tops of the smooth rods. The distance should be 260mm. |

|