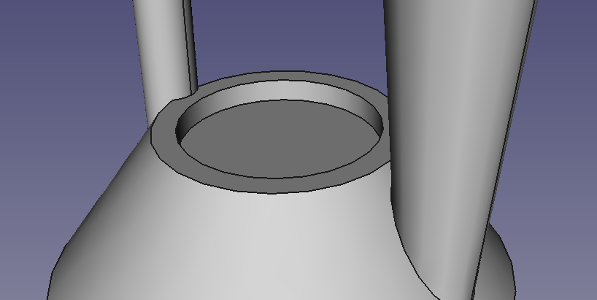

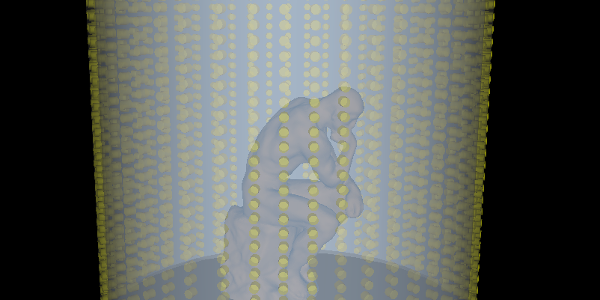

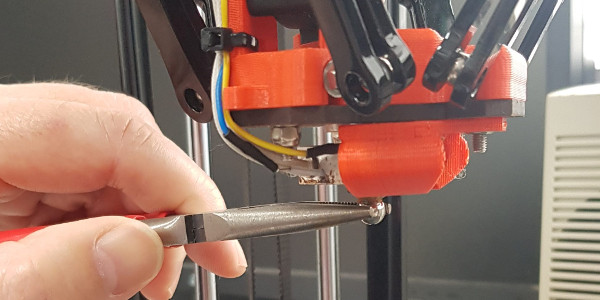

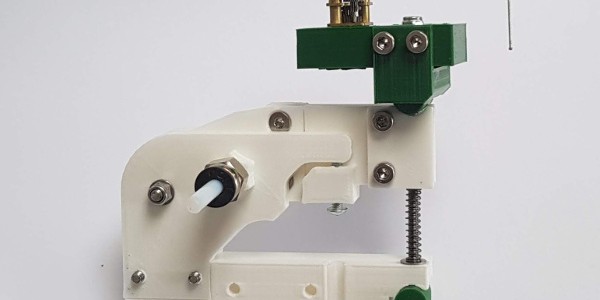

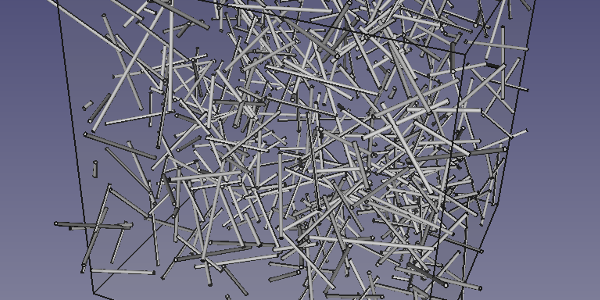

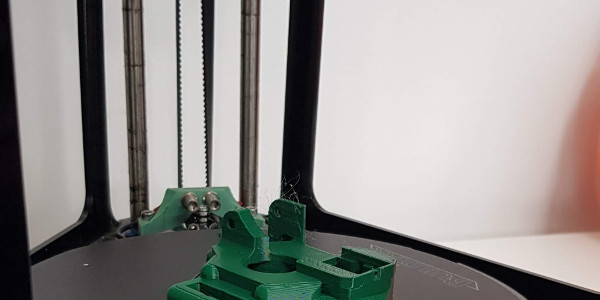

Resin filling FFF 3D prints: other people have done this before, but we have never had occasion to try this until now. We had a heavy heat pump that was being installed in an old stable. Stable floors have a slight

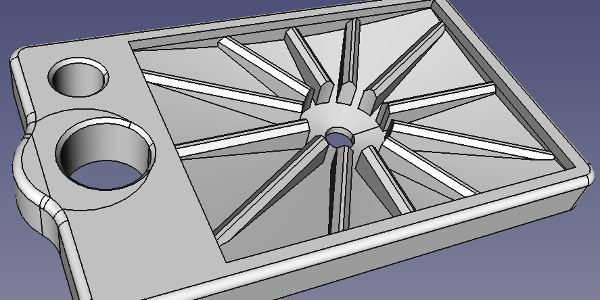

Supporting a 200Kg Load with RepRapped Prints