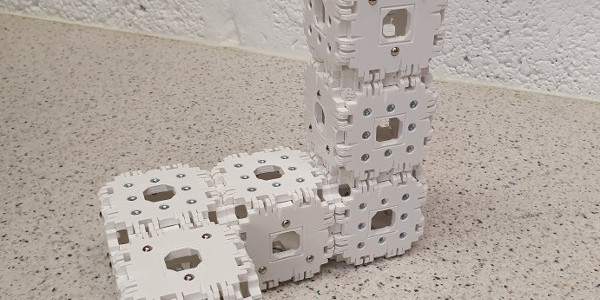

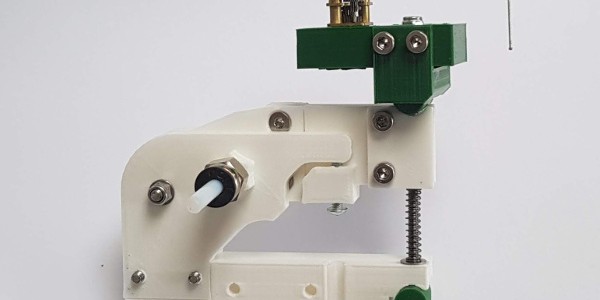

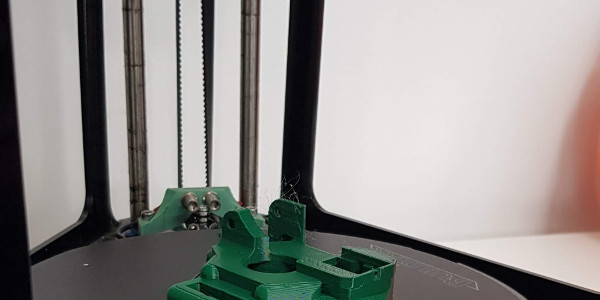

This assembly robot was made by Benjamin Jenett and Neil Gershenfeld at MIT. As you can see, it crawls over the structure it is building placing identical standard cubic blocks wherever it wishes. It is capable of building large-scale structures; structures

RepRap Assembly Robot to Build Itself and More RepRaps