Contents

Wiring the Duet

The Duet electronics board controls all the functions of the printer. We use an external 5V regulator board to provide good, clean 5V power.

|

|

||||||||||||||||||||

Mount the Duet in the enclosure

Assemble the electronics enclosure using the following parts:

| Start by taking the enclosure-base. All the aluminium parts may have oil on them; wipe them over with a paper towel to remove the oil, and any swarf that may be left over from the cutting process. Take 2 x M3x12mm cap head screws, 2 x M3 washers and 2 x M3 nuts, and mount them LOOSELY, as shown. These two screws hold the 5V regulator PCB. |  |

| We’re going to trial mount the Duet PCB, to check that there are no short circuits under boards underneath. Mount the other four M3x12mm cap head screws with an M3 nut each, again LOOSELY, as shown. |  |

| Place the Duet board on the screws. The nuts act as spacers between the Duet board and the enclosure base. |  |

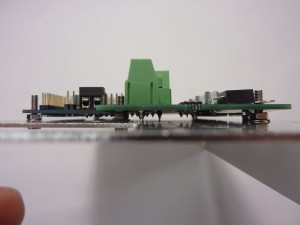

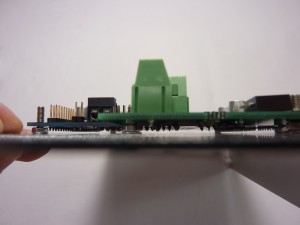

| IMPORTANT: Look between the Duet board and the enclosure base. You do not want any of the soldered pins on the back of the board to touch the metal of the enclosure base. If they are touching and power is applied to the board, it will short circuit, and potentially damage the board. |  |

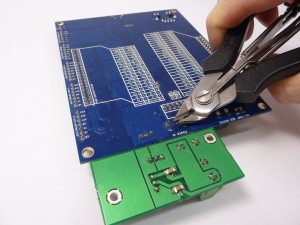

| Trim any long pins with a pair of side cutters. |  |

| Check again that there is nothing in danger of contacting the enclosure base. Once you are happy nothing is touching, remove the Duet assembly, and remove the four cap head screws with just a nut holding them (no washer). If you wish, you can also put strips of Kapton tape (which is electrically insulating) on the enclosure base, under the Duet. |  |

| Take the Duet enclosure perimeter, and fold it until the semi-circular external tag passes through the small slot. CARE SHOULD BE TAKEN WITH ITS SHARP EDGES. Do not bend the tab over yet! There are three slots in the enclosure base at each end, which correspond to the tabs in the enclosure perimeter. Make sure they are aligned, then slot the two parts together as shown; a fair amount of pushing force is required to push the tabs into the slots. |  |

| Secure the Duet perimeter with the four M3x12mm cap head screws, each with an M3 nut. Assemble LOOSELY; the screws need to be able to move a little, to make it easier to fit the Duet board. |  |

| Unhook the part of the Duet perimeter with the external tab, and release the three tabs where it goes into the enclosure base. This should give you the space to put the Duet board in. |  |

| Place the Duet assembly in the enclosure. Line up the screws, so it goes on the mounting holes. |  |

| The USB connector is the longest part. Check it comes through the hole at the end, and that the SD card socket and ethernet socket line up. |  |

| Once the Duet is in place, refit the enclosure perimeter in the tab slots. Bend over the external tab to secure it. Tighten the six mounting screws; if you push down on the board, the M3 nuts should bite enough to tighten. |  |

| Fit the four hexagonal stand-offs on the ends of the mounting screws. This can be quite fiddly, particularly the one by the ethernet socket. To help, screw an M3x8mm countersunk screw into one end of the stand-off, and position the stand-off on the mounting screw with long nosed pliers. Tighten by using an Allen key in the countersunk screw, through the hole in the metal perimeter. Remove the countersunk screw from the stand-off by holding the stand-off with long nosed pliers. Repeat the process until you have tightened all of them. |  |

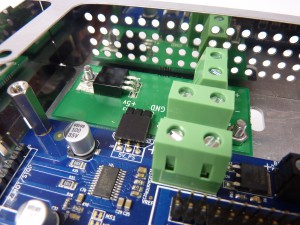

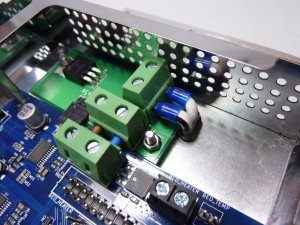

| The last two M3 nuts secure the 5V regulator PCB. The one that goes through the component (the 5V regulator) is particularly important; it is used to heatsink this to the enclosure back. Make sure it is securely fixed. |  |

| Check all the M3x12mm cap head screws are tight underneath, and the Duet board is securely held, and the stand-offs are screwed down fully too. The completed assembly is shown here. |  |

Power supply wiring

|

|

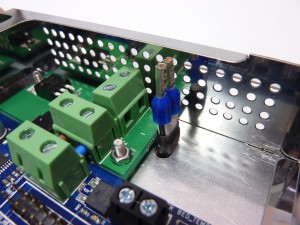

| Pass the ends of the DC power cable up through the slot in the enclosure-base to come out near the power input terminal of the 5v regulator PCB. The wire with the black stripe is used for the V- (ground) terminal. The heat shrink on the cable can act as protection for the wires where they pass through the metal enclosure. |  |

| Check the screw gates are open, then insert the DC power cable ends into the screw terminal. A pair of long-nosed pliers helps. Ensure that the positive (no stripe) and ground (black stripe) wires are the correct way round. |  |

| Tighten the screw terminals on the DC cable ends. |  |

| All of the wires connect to the PSU through insulated spade terminals. Open the small clear connector cover, to access the screws. The brown wire goes to Live, the blue to Neutral, and the green and yellow stripe to Ground/Earth. The Y-shaped earth loop goes from Ground/Earth to the next connector along (COM or Negative/V-). Make sure the screw terminals are tight, and the wires are secure. |  |

Power supply mounts

|

|

| Fit the inner-psu-spacer and inner-psu-plate to the PSU using two M4x12mm button head screws as shown. DO NOT use screws longer than 12mm! They may come in contact with components inside the power supply! |  |

| Flip the PSU over and fit the psu-spacer using two M3x8mm cap head screws. |  |

| Screw the three M3 standoffs into the psu-spacer, sandwiching the psu-cover-spacer. |  |

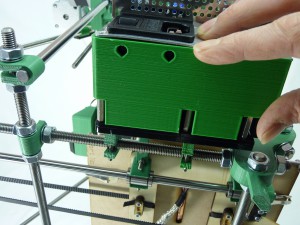

Mounting the Duet on the power supply

|

Picture to come |

| Screw the 12v power cable into the PSU V+ and V- terminals. Ensure to fit the wire with the black line along its length to the V- terminal. |  |

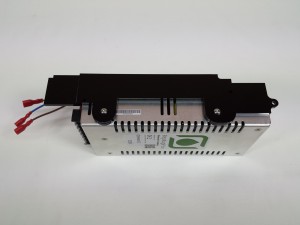

| Mount the Duet enclosure to the PSU assembly using the M3x8mm cap head screws as shown. |  |

Fitting the IEC socket

|

needs pic |

| Push the fuse holder out of the socket. There is a hole in the bottom of the socket; use an Allen key to push it out. |  |

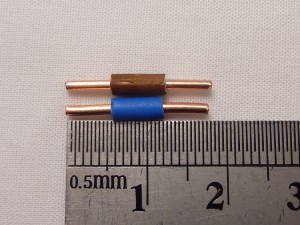

| Insert the fuse into the holder as shown. There is space to put a second, spare, fuse in the square hole. |  |

| Push the fuse and fuse holder back in. There is a tab on one side, which fits in a slot in the socket. This means the fuse cannot be removed with the power cord plugged in. |  |

| Push the fuse holder down until it is flush with the surface. |  |

| Connect the mains wires to the spade terminals on the back of the IEC socket as shown. |  |

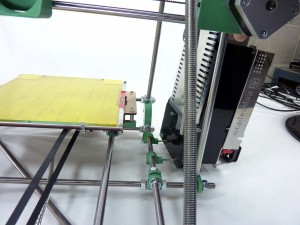

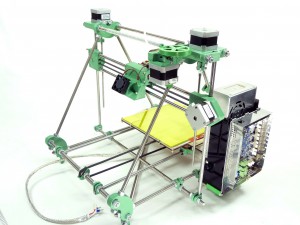

Mounting PSU and Duet on printer

|

Picture to come |

| First fit the remaining laser cut part to the power supply. using the two M4 x10 button head screws. |  |

| Fit the m3 nuts into the electronic bar clamps. The correct ones have the M3 nut recesses. |  |

| Clip this mounts onto the frame at the bottom behind the X Motor. |  |

| Insert two M3x30mm cap screws into the PSU spacer |  |

| Using the captive nuts in the electronic bar clamps and the cap screws just fitted, loosely attach to the frame so that it can still slide side to side. |  |

| Repeat this process using the final M3x30mm cap screw and the other bar clamp. However no nut is required, instead the head of the cap screw sits in the clamp, and this is threaded into the power supply itself.Snap the clamp onto the frame and insert the cap screw. |  |

| Adjust the clamp so that it lines up with the threaded hole in the power supply, and tighten the cap screw. |  |

| Now tighten the cap screws in the other clamps. |  |

| Push the IEC socket into the aperture in the enclosure base, with the power cord socket on the outside edge. Push the wires back into the housing and push the IEC socket into the aperture until it clicks. |  |

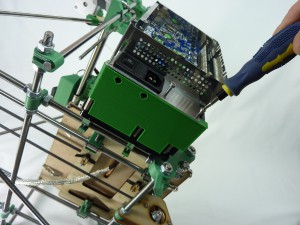

| Fit the PSU cover cover into the cavity…. |  |

| …and secure with 3X M3x50 cap screws. |  |

| Electronics fitted… |  |