The idea for this work and this blog post came from Youtuber Skyentific. So hat-tip to him, and do take a look at his channel. Ravigneaux epicyclic gears are a compact way to make a gearbox with a large

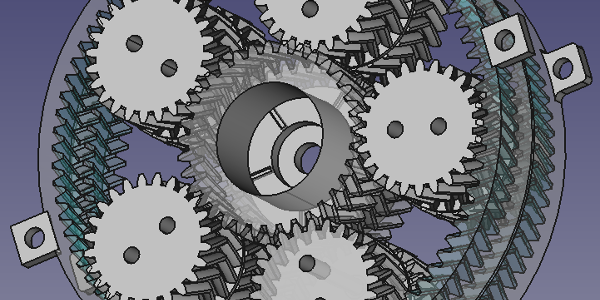

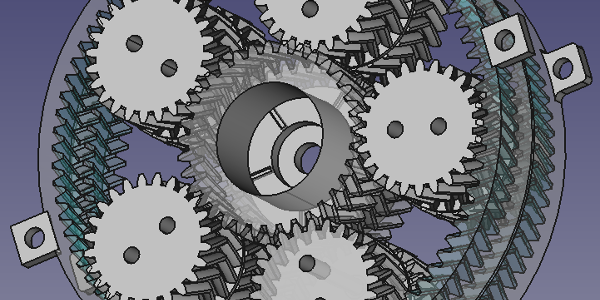

Printing Ravigneaux Epicyclic Gearboxes

The idea for this work and this blog post came from Youtuber Skyentific. So hat-tip to him, and do take a look at his channel. Ravigneaux epicyclic gears are a compact way to make a gearbox with a large

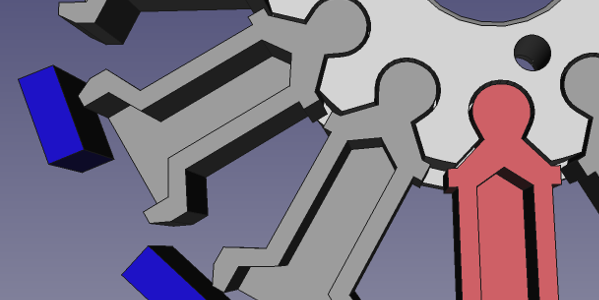

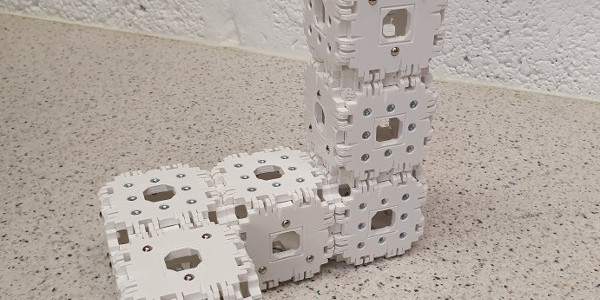

It’s often the case that you need to 3D-print objects that must slot together, like the grey and red parts slotting into the white central hub in the picture above. (It’s a design for a 3D-printed BLDC motor that we’re

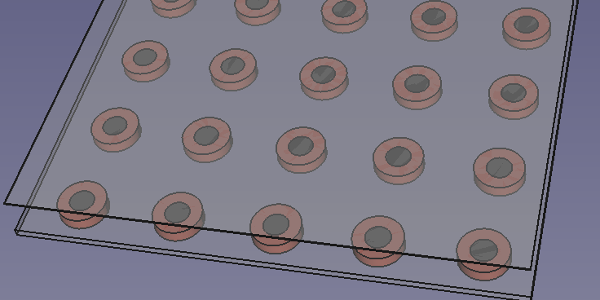

Part 1 of this sequence of blog posts is here. This post assumes that you have read that one first. Summary (TL;DR) We made a photochromic neuron, but it suffered from a problem: the photochromic material was not fully reversible,

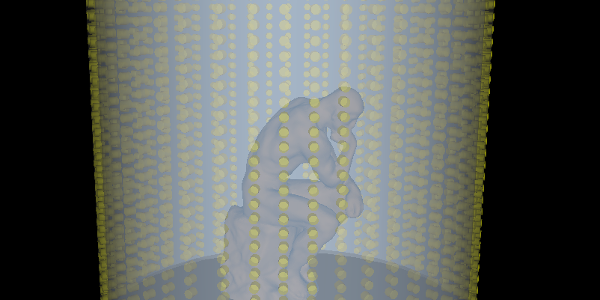

Summary (TL;DR) This describes a working design for an optical neural-net synapse that will use photons to transmit a weighted signal to a summing optoelectronic artificial neuron. We also have a design for the neuron itself, which we will build

RepRap (and other) FFF 3D printers have had heated beds to ensure prints don’t peel off for a long time. I think they were invented by Chris Palmer (Nophead) in 2010. They have also had magnetic beds to hold

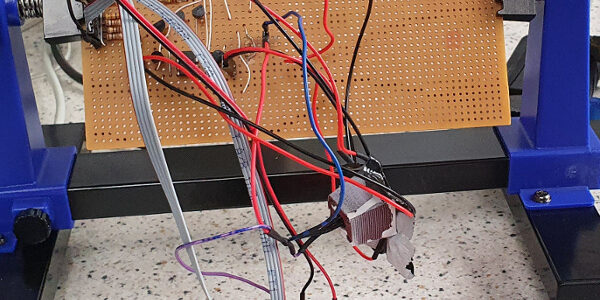

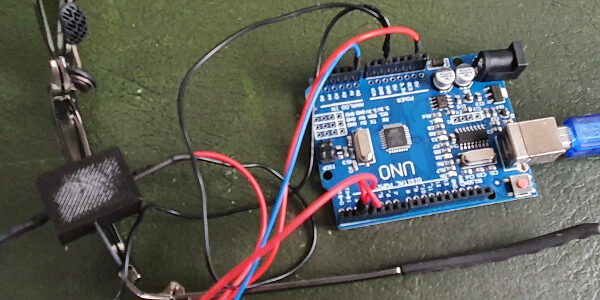

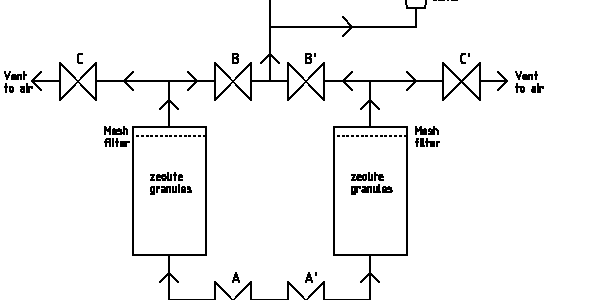

[NOTE: This is still in development, and it is NOT YET WORKING. Since this blog post was written we have done more work on this idea, and so the diagram above and the post are now out-of-date. For

This assembly robot was made by Benjamin Jenett and Neil Gershenfeld at MIT. As you can see, it crawls over the structure it is building placing identical standard cubic blocks wherever it wishes. It is capable of building large-scale structures; structures

We now have a Github repository for all the work on this project here. See that link for the entire project log. If we want to print a shape, one of the things it would be useful to know is the

[For the latest on this idea, see our documentation here.] This blog post combines three ideas to make a fourth. The three are: The reverse-CT scan 3D printing technique from Berkeley and Lawrence Livermore, The open-source electric 3D scanning technique for

Most recycling streams are not set up to process PLA, despite the fact that PLA is probably the most widely-used 3D printed material and is easy to recycle in a number of ways. This needs to change, and the 3D