Contents

Overview

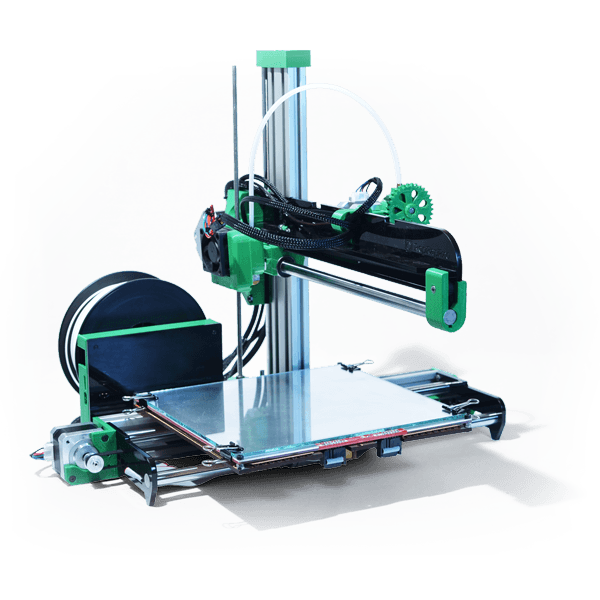

The RepRap Pro Ormerod design is the latest from RepRap Pro. The machine is a faster to assemble, networked 3D printer with non contact bed probe for full geometric compensation.

These pages are the complete instructions for building, commissioning and using the RepRapPro Ltd version of RepRap Ormerod. Like all RepRap machines, RepRapPro Ormerod is fully open-source. It is licensed under the GPL. All the design files and software are available from the RepRapPro Ltd Github repository.

The RepRapPro Ormerod is fitted with the open source Duet electronics.

If you want to print the plastic parts for a RepRapPro Ormerod, see this wiki page.

General notes

- BEFORE YOU ATTEMPT TO ASSEMBLE ANY PART OF THE RepRapPro ORMEROD 3D PRINTER, PLEASE READ THESE BUILD INSTRUCTIONS FULLY AND ENSURE YOU UNDERSTAND THEM. Although all parts are covered by warranty, this will be invalidated by your not following these build instructions. You are building a complex machine; many different skills are required to build, commission and operate a 3D printer. Try not to rush your build, or you may miss out something vital!

- Give yourself plenty of space and ensure your work area is clean. Dust and dirt are a 3D printer’s worst enemy.

- All printed parts have been printed on RepRapPro’s own machines. Despite the fact that these machines are highly tuned RepRap 3D printers, some holes and features may need a little fettling to get the best performance from the RepRapPro Ormerod. There is a video how-to on fettling 3D printed parts here on Vimeo.

- Before you start the build, please ensure you have all the components as listed on the packing list included in the kit. If anything is missing or damaged, please contact us through our contact page.

- We understand that people may want to change aspects of the machine’s design, and in fact we encourage this as it is one of the benefits of open source development. Before changing anything, please be aware that the RepRapPro Ormerod has been designed to maximise the build volume relative to the the machine’s footprint, and as such many of its components fit closely to others. So consider your changes carefully before you try to implement them. And when you find improvements, please tell us so that we can include them in future kits, and so that existing owners can upgrade their own machines.

- The RepRapPro Ormerod is a robust RepRap machine once assembled; however it does require a certain amount of care during assembly. If in doubt, force is usually not the answer! There are many ways to get support and advice; see below.

Get support

If you find you need help or advice with assembling, commissioning or using your RepRapPro Ormerod 3d printer, you can use the following channels:

- Check the instructions again; we are regularly updating them with feedback from our growing user-base.

- Contact the support department of the company that sold you your printer.

- Check the RepRap community forum, Ormerod section.

- Contact us on our irc (internet relay chat) channel RepRapPro on freenode irc

- Contact us via email; see our contact page.

Archived documents for older versions

If you have an older RepRapPro Ormerod and want a past copy of this documentation see these links:

- N/A

Tool List

Mechanical

Tools required for the mechanical build of the RepRapPro Ormerod 3D printer:

- Allen keys: 1.5mm, 2mm, 2.5mm, 4mm (the long reach type, with a ‘ball’ hex on the end, are very useful)

- Drills: 2mm, 3mm, 4mm

- Hand chuck, pin vice or small electric drill

- 9mm spanner (M5 nut)

- 15cm adjustable spanner

- File

- Half round needle file

- Craft knife

- Fine tweezers

- 300mm rule

- Vernier or digital callipers

- Square

- Fine nosed pliers

- Pliers

- Adjustable grips, Mole grips or bench vice

- Pencil sharpener

Electrical

- Digital Multimeter

- Precision screwdrivers

- Hot air gun, or cigarette lighter (or other heat source for heating ptfe heatshrink – a hair dryer is not sufficient)

- Wire strippers/cutters

- Crimping tool (very useful, but not absolutely necessary; you can do it by hand)

- EITHER Ratchet crimp tool Such as this one, which we use

- OR Molex crimp tool (such as the 63811-1000, you may also want the extraction tool 11-03-0044, Molexkits.com)

- Scissors