Build Instructions – Base Assembly – Tower Assembly – Panels and Rods – Effector Assembly – Extruder Drive

Hot End Assembly – Electronics – Bed, Top Plate and Belts – Commissioning – Printing – Troubleshooting

Goal

By the end of this section, you will have assembled the base of the printer.

| TIP: Click on pictures in the instructions to see a larger version. |

Tower Construction

There are three towers that support the three moving arms of the printer. For each tower you will need the following parts:

| TIP: There’s a list of the Fisher printed parts on THIS PAGE. Click on the ‘Location’, to see a preview of the printed part, if you are unsure what it is. |

| NOTE: The smooth rods should have clean chamfered ends, free from burrs, so they can slide easily into the relevant parts without causing any damage. Check all the ground bars before proceeding and file any burrs away as necessary. You may damage the linear bearings when you fit them if you do not do this. |

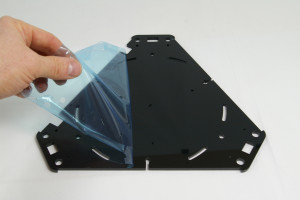

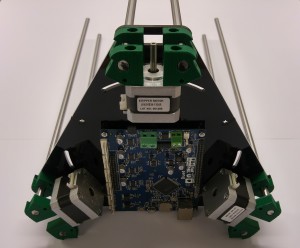

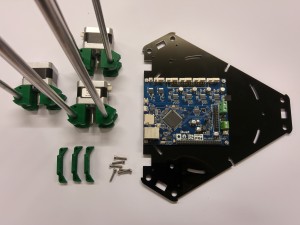

Base Plate Assembly

The base plate holds the electronics. You will need the following parts:

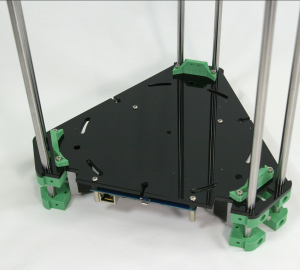

Base Assembly

Assemble the lower part of the printer. You will need the following parts:

| # | Component | Qty | Type | |

| Motor towers | 3 | Assembled |  |

|

| Base | 1 | Assembled | ||

| 1245 | Kinematic Mount | 3 | Printed | |

| 242 | M3x16mm cap head screw | 6 | Fasteners |

Back – Overview Next – Tower Assembly