Build Instructions – Base Assembly – Tower Assembly – Panels and Rods – Effector Assembly – Extruder Drive

Hot End Assembly – Electronics – Bed, Top Plate and Belts – Commissioning – Printing – Troubleshooting

Goal

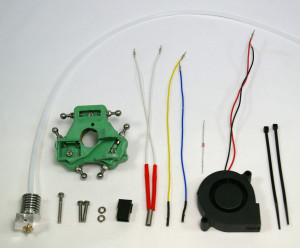

By the end of this section, you will have built the hot end, assembled it with the effector,

and installed it in the printer frame.

The hot end melts the filament, and extrudes it, to build the 3D printed object.

(The image shows a terminator on the free end of the PTFE tube. This is no longer needed.)

Crimps

These are the small metal pins and sockets attached to the ends of wires by pinching parts of themselves (“crimping”) to grip the wire. The ends of the fan, thermistor and heater wires are fitted with crimps pinched onto the ends of their wires. There are many types and shapes. The ones fitted onto the hot end components are designed to fit into a connector block. The barbs on them latch onto plastic tags inside the slots of the connector block, holding them in place. It is therefore important to insert them the right way round so they fit correctly and click into place, and to be aware that once they’re in, they’re very difficult to get out again.

Assemble the Hot End Components

Nozzle Assembly

The nozzle is where the filament is heated and extruded from. You will need the following parts:

| # |

Component |

Qty |

Type |

|

| 1180 |

Tapered nut |

1 |

Hot end |

|

| 739 |

Heater block |

1 |

Hot end |

| 1179 |

Threaded nozzle |

1 |

Hot end |

| 1136.1 |

Heatsink |

1 |

Hot end |

| 1055 |

Bowden Tube |

1 |

Hot end |

| Screw the nozzle into the base of the heatsink by hand. |

|

| Screw the heater block onto the nozzle, again by hand. There is not need to use any tools at this stage. Take care to fit the heater block with the small hole nearest the nozzle tip. |

|

| Fit the brass nut. Using an 8mm spanner, gently tighten the assembly until it is just over ‘finger tight’. Hold the heater block and tighten the nut, leaving the heatsink and nozzle free to rotate. The constriction in the nozzle has a very thin wall (to reduce heat conduction), so care should be taken not to over tighten the assembly as it may result in snapping the nozzle. |

|

| Screw in the pneumatic fitting to the heatsink. There is no need to use a spanner, hand tightening is sufficient. |

|

| Check the ends of the PTFE Bowden tube are clean and cut square. If needed, use a scalpel or craft knife to make a clean cut. |

|

| Insert the Bowden tube into the pneumatic fitting. |

|

| The pneumatic fittings grip the PTFE tube tightly. But if, by mistake, you try to drive filament into the hot end when it is too cold the tube can sometimes slip out a little way. This is hard to see. So put a short piece of sticky tape round the PTFE tube as shown so it just touches the top of the pneumatic fitting. Then in the future you will be able to see if a gap opens up.

Add another piece of tape to the PTFE tube where it goes into the pneumatic fitting on the extruder drive.

If a gap opens up later, push the tube back in with the hot end at full temperature. Be careful not to touch the hot part of the hot end. Then extrude, say, 100mm of filament to clear the hot end through. |

|

Test the Cartridge Heater

The cartridge heater provides the heat for the hot end.

You will need the following parts:

| # |

Component |

Qty |

Type |

|

| 662 |

Cartridge heater 19v |

1 |

Hot end |

|

| Check the resistance of the heater cartridge. It should be around 10 to 11 ohms. |

|

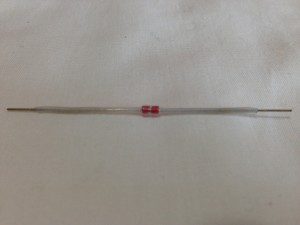

Thermistor

The thermistor is the temperature sensor for the hot end, and makes sure the hot end stays at the correct temperature. You will need the following parts:

| # |

Component |

Qty |

Type |

|

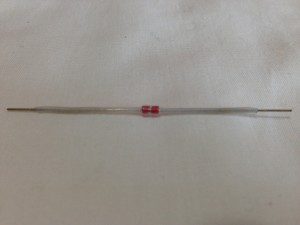

| 430 & 167 |

Thermistor with PTFE heatshring surround |

1 |

Hot end |

|

The thermistor supplied with our kits comes with the PTFE heatshrink pre-shrunk on to it.

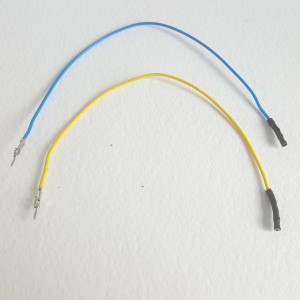

Thermistor Wires

These wires connect the thermistor to the wiring loom.

| # |

Component |

Qty |

Type |

|

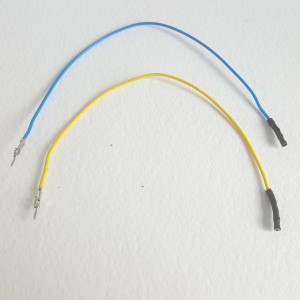

| 433 |

Thermistor wiring – 160mm |

2 |

Hot end |

|

| Thermistor wires should each have the female crimp wrapped in heatshrink. |

|

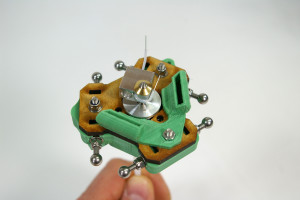

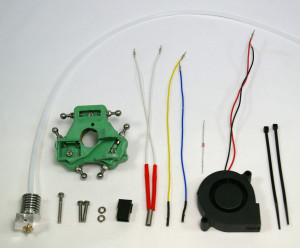

Assemble the Hot End and Effector

The hot end is mounted in the effector. You will need the following parts:

| # |

Component |

Qty |

Type |

|

|

Hot end assembly |

1 |

Assembled |

|

|

Effector assembly |

1 |

Assembled |

| 112 |

M3x25mm cap head screw |

1 |

Fastener |

| 257 |

M3x12mm cap head screw |

2 |

Fastener |

| 212 |

M3 plain washer |

2 |

Fastener |

| 368 |

3×2 Female Housing (3020-06) |

1 |

Hot end |

| 662 |

Cartridge heater 19v |

1 |

Hot end |

| 433 |

Thermistor wiring -160mm |

2 |

Hot end |

| 430 |

Thermistor (insulated) |

1 |

Hot end |

| 1194 |

50mm blower fan – 160mm crimped |

1 |

Electronics |

| 133 |

Cable ties 2mm |

2 |

Electronics |

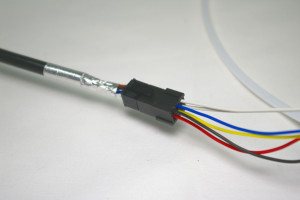

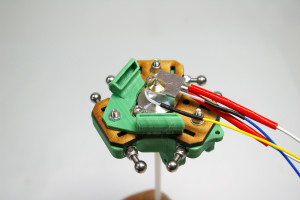

Adding the Heater, Thermistor and Fan

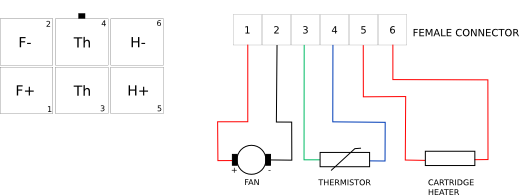

Hot End Wiring

| CAUTION! The next step describes wiring up the hot end connector. GREAT CARE should be taken doing this. The heater cartridge and the fan wires have 19V running through them ALL THE TIME. The thermistor wires are 3.3V, and connect directly to the Arduino chip on the Duet controller board. If you incorrectly wire the plug, a short circuit between the thermistor wires and any of the other wires MAY DESTROY YOUR DUET! |

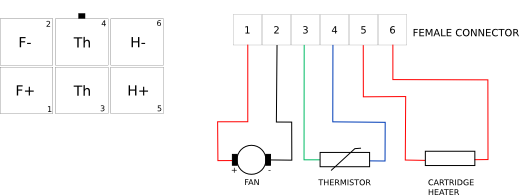

Wiring diagram

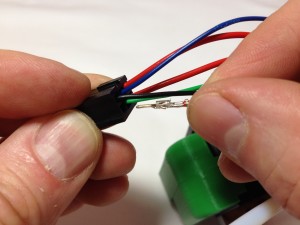

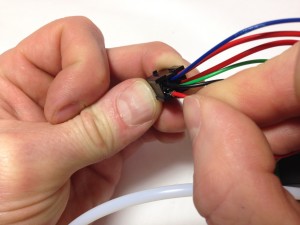

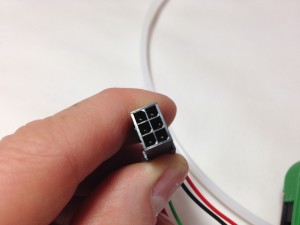

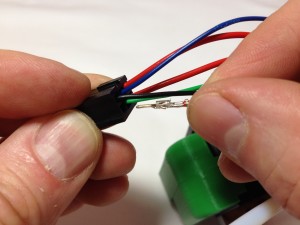

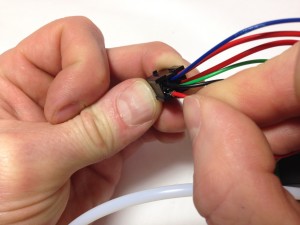

| Put the pins on the ends of the wires into the six-way female socket. The wiring diagram, above, is looking into the back of the socket, where you insert the crimps. The little black rectangle is the locking tab, and the housing has small embossed ‘1’ and ‘6’ numbers on it, so you can orientate it as the diagram. The pins are crimped on one side, and smooth on the other. The smooth sides go downwards in the diagram. |

|

| Neither the thermistor nor the heater cartridge have a polarity so it doesn’t matter which way round their wires go. (Though the H+ and H- are the way that the machine will apply power – hence the labels.) Make sure to get the polarity of the fan right. This picture shows one of the fan wires being put into the housing, but it is not fully in yet; you can’t see the crimp easily when it is. |

|

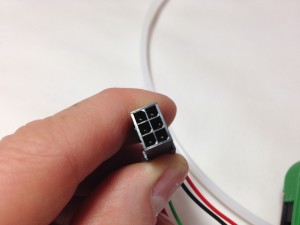

| Check that the pins are all the same depth into the housing. The pins are very difficult to remove without damaging them, so check twice, plug in once! They should click into place, and then shouldn’t easily push further through, or pull back out. |

|

Wire Colours Related to Hot End Wiring Loom

Note below that the colours ether side of the connector do not all match up. This is because of backwards compatibility with other designs. Make sure you do what it says in this table.

| Wiring loom |

Hot end wires |

| 1 Yellow |

Red FAN wire (+19V) |

| 2 White |

Black FAN wire (ground) |

| 3 Green |

Yellow Thermistor wire (3.3V) |

| 4 Blue |

Blue Thermistor wire (3.3V) |

| 5 Purple |

Orange or white heater wire (+19V) |

| 5 Black |

| 6 Red |

Orange or white heater wire (ground) |

| 6 Brown |

| You can check the wire order by comparing it to the end of the hot end loom, which the hot end plugs into. |

|

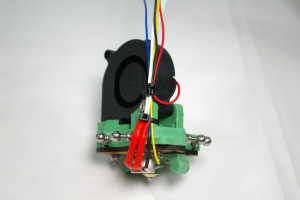

Mounting the Effector

| If you wish you may put a little silicone grease on the six effector balls to lubricate them and the rods. But don’t use mineral-oil based grease as this may damage the rods.

Orientate the effector so the fan is facing the open side of the printer. As you did when connecting the rods to the carriages, gently prise the rod ends apart, and slip them over the balls of the effector. Tighten the grip of the rods on the stainless steel balls, by tightening the M3x8mm cap head screws on the rods. |

|

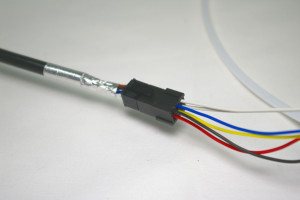

| The printer so far.

(The image shows a terminator on the free end of the PTFE tube. This is no longer needed.) |

|

Back – Extruder Drive Next – Electronics